How To Heat Print Trucker Caps

How To Heat Print Trucker Caps

The trucker cap started out in the 1960s and '70s as a giveaway item from agricultural companies, feed stores, and truck stops. These caps were cheap to make, breathable (thanks to their mesh back), and had a big front panel perfect for logos. They were primarily worn by truckers, farmers, and blue-collar workers—hence the name.

The use of trucker caps began to shift in the early 2000's with brands like Von Dutch turning the trucker cap into a fashion statement. Celebrities like Ashton Kutcher, Britney Spears, and Pharrell Williams were often photographed wearing them and this trend soon filtered through into pop culture and streetwear. And it's thanks to this journey that the trucker cap is as popular as it is today.

Why people love the trucker cap in the 2020's:

- Logo canvas: The foam front is great for logos, slogans, or graphics—perfect for brand identity.

- Casual cool: It signals a laid-back, unpolished vibe.

- Breathability + comfort: Functionally, they’re light and comfortable, especially for warmer weather.

- Nostalgia factor: Taps into memories of childhood, early 2000s culture, or Americana.

Did you know the Trucker Cap is one of the easiest caps to heat print?

Heat printing on trucker caps is incredibly easy, thanks to the smooth foam front panel. This flat surface is ideal for applying heat transfers, something not often found in most caps. Traditional 6-panel caps typically feature a center seam across the front, which makes heat transfer application tricky or even impossible. With trucker caps, that issue is eliminated. Plus, the foam front prevents any unwanted fabric texture from showing through, making it perfect for thinner, more flexible transfer types like UltraColour MAX DTF, which some printers might otherwise avoid.

Today we're starting with the Beechfield Brands BC645 Vintage Snapback trucker cap. It comes in 13 shades including a black with a black panel instead of white.

The front panel is made up of 100% polyester which despite everything we normally teach when heat printing, handles heat extremely well. Due to the light colouring of the polyester, scorching is not visible meaning you can use any temperature heat transfer.

The heat press we're using in this blog is the Hotronix 360IQ Hat Press. It has dual heated platens meaning that if you switch to the black on black colourway, you can set your lower platen higher, upper platen lower, and minimise any visible scorch marks.

This also means, that when using this heat press, you save time on pre-pressing because the lower heated platen heats the cap from the moment you lock it into place.

Heat Transfers

When printing caps, it's commonly taught to opt for slightly thicker heat transfers. This helps mask any cotton twill texture that might show through once the transfer applies and conforms to the shape of the cap. As a result, UltraColour or InkTra with a Subli-blocking backer are a great choice, unless you're using a heat-applied badge, which is already thick enough.

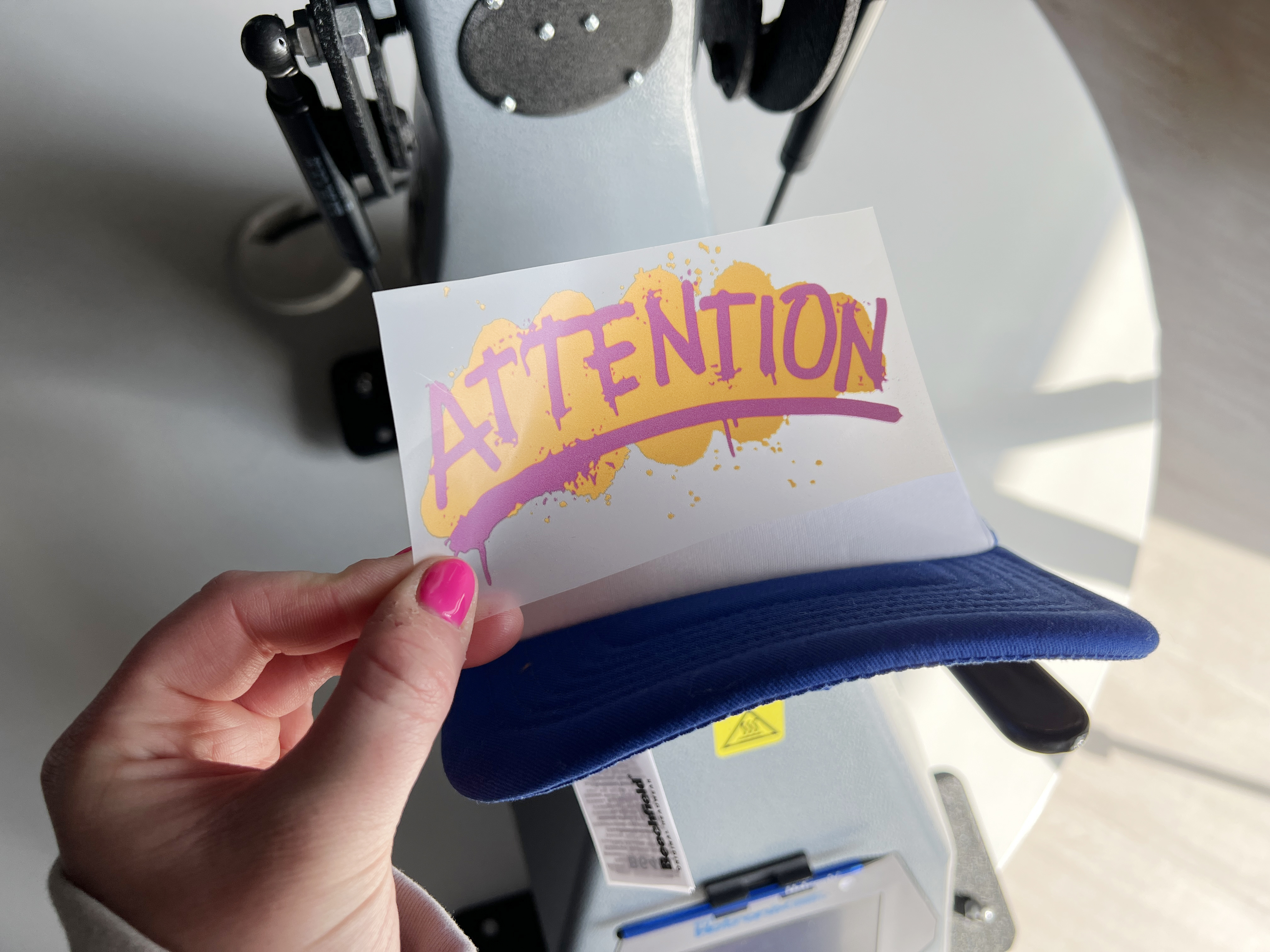

What sets this foam front trucker cap apart from other caps is its smooth, texture-free surface, which eliminates that concern entirely. This opens the door to using thinner, more flexible transfers like UltraColour MAX DTF.

With Stahls’ UltraColour MAX DTF transfers requiring a minimum order of just one, this combo is perfect for small runs, personalisation, or sampling. Simply gang multiple designs onto a larger sheet, place a single order, and you’re ready to start printing.

Application

The recommended application instructions for UltraColour MAX DTF is 145°C for 12 seconds onto clothes. However, when working with the Hotronix 360IQ Cap Press, you have two heated platens to think about. When fusing this trucker cap, we set the upper platen to 125°C and the lower to the original 145°C. This upper temperature ensures that you're minimising any visible scorching on the outside.

It's worth noting that we had no need to use the foam pressure distribution pad that is recommended with chunkier decoration methods.

Pressure setting - 5

Application time: 12 seconds

Temperature: 125°C/145°C

Conclusion

Trucker caps offer a standout opportunity for heat printers looking to expand their product range with minimal hassle. Their foam front panel not only makes them easy to work with but also delivers smooth, professional results, especially with modern transfer types like UltraColour MAX DTF. Whether you're creating custom merch, promotional giveaways, or retail-ready headwear, trucker caps combine style, comfort, and printability in a way few other caps can match. Ready to elevate your cap game? Trucker caps might just be your next bestseller.