Understanding Heat Transfer Temperatures: What Works Best for Different Fabrics?

Understanding Heat Transfer Temperatures: What Works Best for Different Fabrics?

Heat transfer printing has become one of the most popular methods for customizing apparel, but achieving perfect results requires more than just a good design and a heat press.

One of the most important factors to consider is heat transfer temperature. The temperature at which you apply heat plays a significant role in the success of your print, especially when working with different types of fabrics. Each fabric responds differently to heat, and knowing the right temperature for each material can mean the difference between a flawless print and a ruined garment.

Different fabrics, from cotton to polyester to performance fabrics, each have unique properties that make them either heat-sensitive or heat-resistant. For example, polyester, which is commonly used in sportswear, requires lower heat to avoid dye migration, while cotton can withstand higher temperatures due to its durability. Performance fabrics, like those used in athletic wear, often feature blends that require a careful balance of heat, pressure, and time to ensure optimal results.

In this blog, we’ll guide you through the essential factors to consider when determining the right heat transfer temperature for various fabrics. From understanding ideal temperature ranges for common fabrics to knowing how to prevent damage such as scorching, dye migration, or fabric warping, this comprehensive guide will give you the tools and knowledge you need to achieve professional-quality prints. Whether you’re printing for fashion, sportswear, or custom designs, mastering heat transfer temperatures is key to ensuring vibrant, durable, and long-lasting results.

Main Types of Fabric Blends

Fabric blends are created by combining different fibers to enhance the properties of a material, such as strength, comfort, durability, or stretchability. While you may not be manufacturing the blank garment your business requires yourself, you still need to pay special attention to its ingredient blend to know how to decorate it correctly.

Here are some of the most common fabric blends you'll encounter:

1. Cotton

Characteristics: Cotton fibers are soft, making cotton t-shirts feel comfortable and gentle on the skin.

Uses: T-shirts, Everyday wear.

Benefits: Absorbent, breathable and soft.

2. Cotton-Polyester Blend

Characteristics: Combines the softness of cotton with the durability and wrinkle-resistance of polyester.

Uses: T-shirts, casual wear, uniforms, and sweatshirts.

Benefits: Offers breathability, comfort, and less shrinkage than 100% cotton.

3. Polyester-Elastane Blend

Characteristics: Combines polyester's durability and moisture-wicking properties with spandex's elasticity.

Uses: Athletic wear, swimwear, leggings, and compression garments.

Benefits: Stretchy, moisture-wicking, and quick-drying—ideal for performance fabrics.

4. Nylon-Elastane Blend

Characteristics: A blend of nylon, known for its strength, with spandex for stretch.

Uses: Swimwear, leggings, sportswear, and dancewear.

Benefits: Strong, lightweight, and stretchy with excellent resistance to abrasion and water.

5. Rayon-Polyester Blend

Characteristics: A mix of rayon’s silk-like feel with polyester’s strength.

Uses: Dresses, blouses, skirts, and casual wear.

Benefits: Soft, breathable, and drapes well, offering a comfortable fit with less wrinkle-prone fabric.

Why Fabric Blends Matter

Fabric blends are carefully engineered to combine the best qualities of different fibers, creating versatile materials that serve a wide range of purposes, from everyday clothing to specialized performance wear. The right blend can improve the feel, durability, and functionality of a fabric, making it an ideal choice for specific applications, such as sportswear, workwear, or fashion garments. However, the wrong application method for the right fabric blend might result in a poorly applied decoration method, scorch marks or even unwanted dye migration.

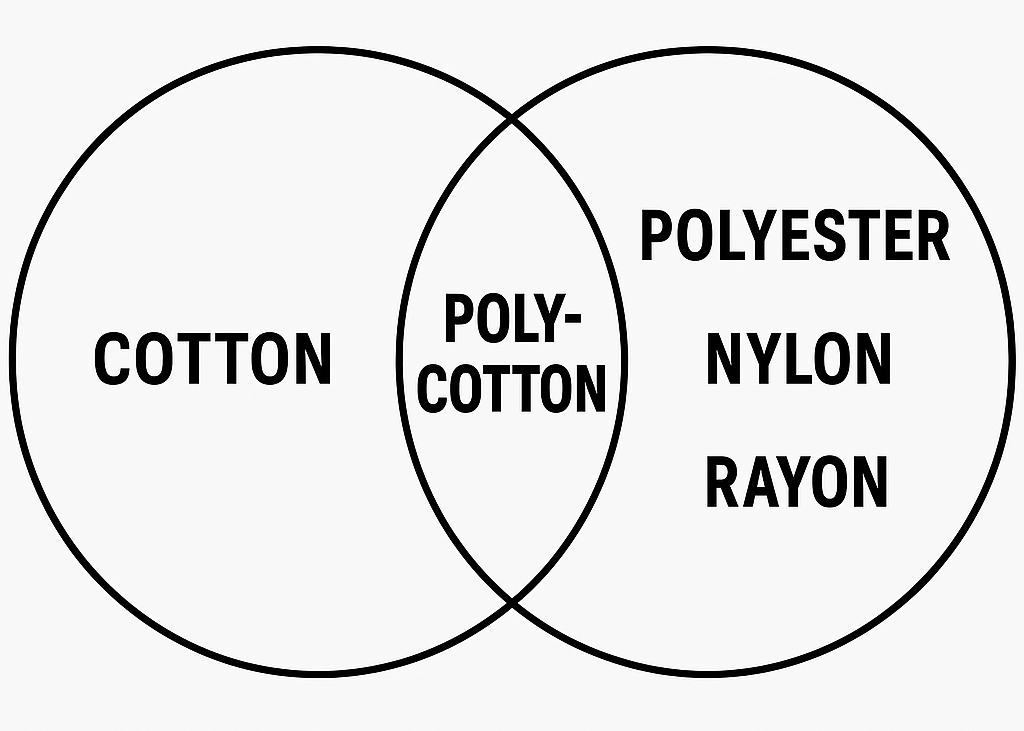

While the above list of materials may seem overwhelming when it comes to building successful application methods, you really only need to split that list into two sections:

Heat-friendly & Heat-Sensitive materials.

While these categories are not gospel, and we still recommend testing every new fabric you come across, these categories will equip you better when it comes to getting started.

Heat-Friendly Fabrics

- Cotton

- Some Poly-Cotton

Heat Sensitive Fabrics

- Polyester

- Nylon

- Rayon

- Elastane

By categorising these materials into two simple methods, we can now assign them print methods.

Heat-friendly fabrics like Cotton and some Poly-Cotton can be printed up to 150°C/160°C, which includes most print methods and temperatures:

- InkTra / Screen Print Transfers - 160°C

- UltraColour PRO Transfers - 125°C

- Stahls' CAD-CUT HTV choices 150-170°C

Heat-sensitive fabrics like Polyester, Elastance, Nylon and Rayon need more care when heat printing and should be printed at temperatures below the scorch-line (130°C):

- UltraColour PRO Transfers - 125°C

By starting off with the correct application temperature, you reduce any wasted time and financial loss of ruined garments and inappropriate decoration methods.

Still scorching at an application temperature of below 130 °C?

This is rare, but can happen with some fabric blends. Check out the A.R.C.H method in the below video. This four-step process takes you through different techniques and accessories that can be used to eliminate scorch marks. Working in order of severity.