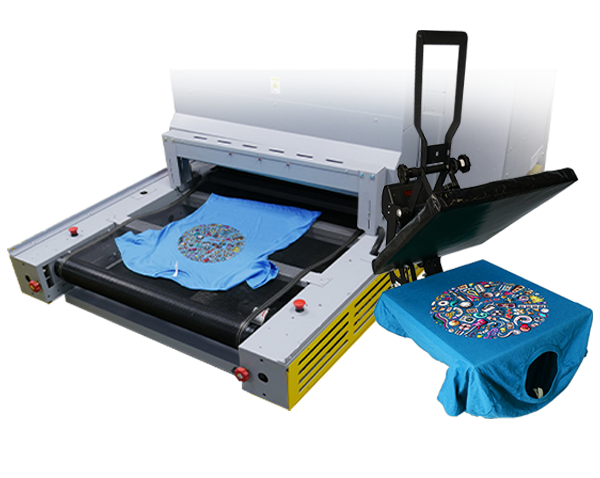

Introducing the Freejet 330TX Plus DTG Printer

Hotronix® & Omniprint International Solutions From The Garment Decoration Specialist

Target Transfers is the UK’s leading supplier of heat applied materials and machines. Part of the Stahls’ and Hotronix group, we are already the manufacturer of the leading heat press for curing your DTG designs. Now we can exclusivley provide the full FreeJetTX Plus DTG solution from Omniprint for you in late 2021 in the UK.

-

Super fast with no rip time

-

Best quality prints in DTG

-

Print more product ranges with Gamut Plus Inks™

-

Wetcap system prevents head clogs

-

Automatic laser height adjustment

-

The lowest production costs - bulk ink saves you money

-

Removable platens - print tees, hats, hoodies and more

The freejet 330TX plus print engine moves over your product dramatically increasing print quality because your product does not move during the print like other systems. High resolution prints achievable up to 5760 dpi on dark and light garments using a combination of our DirectRip technology and our Gamut Plus Inks.

One Pass Print Technology*

Our one pass technology dramatically increases print speeds by allowing the simultaneous printing of the white layer and color layer in the same print pass.* *includes additional cost

Production Speed Mode

When production speeds are the most important the production speed mode allows you to print faster while still keeping a high quality print*

The key to choosing your DTG solution is understanding the Direct To Garment Process.

WHAT IS THE DTG PROCESS?

Step 1 – Pretreat and Cure the Garment

When printing with white ink, apply the proper amount of pretreat depending on the garment preferably with a Brother-recommended pre-treatment machine for optimal results. Then simply cure the pretreat solution with either a heat press or dryer to ensure a flat printing surface.

Step 2 – Prepare the Digital Art

Load your artwork into our new Omniprint software.

Step 3 – Printing on the Garment

Dress the platen with your desired garment or substrate and press print.

Step 4 – Cure the Ink on the Garment

Place the printed garment on to the heat press once again or in a forced air dryer to cure the ink.

This will ensure the ink is fully cured to the garment and will have the desired washability.

YOUR JOURNEY STARTS HERE

Target Transfers Ltd are exclusive Resellers for supply, distribution, support and installation in the UK (United Kingdom) of Omniprint printers equipment, supplies, accessories and inks.