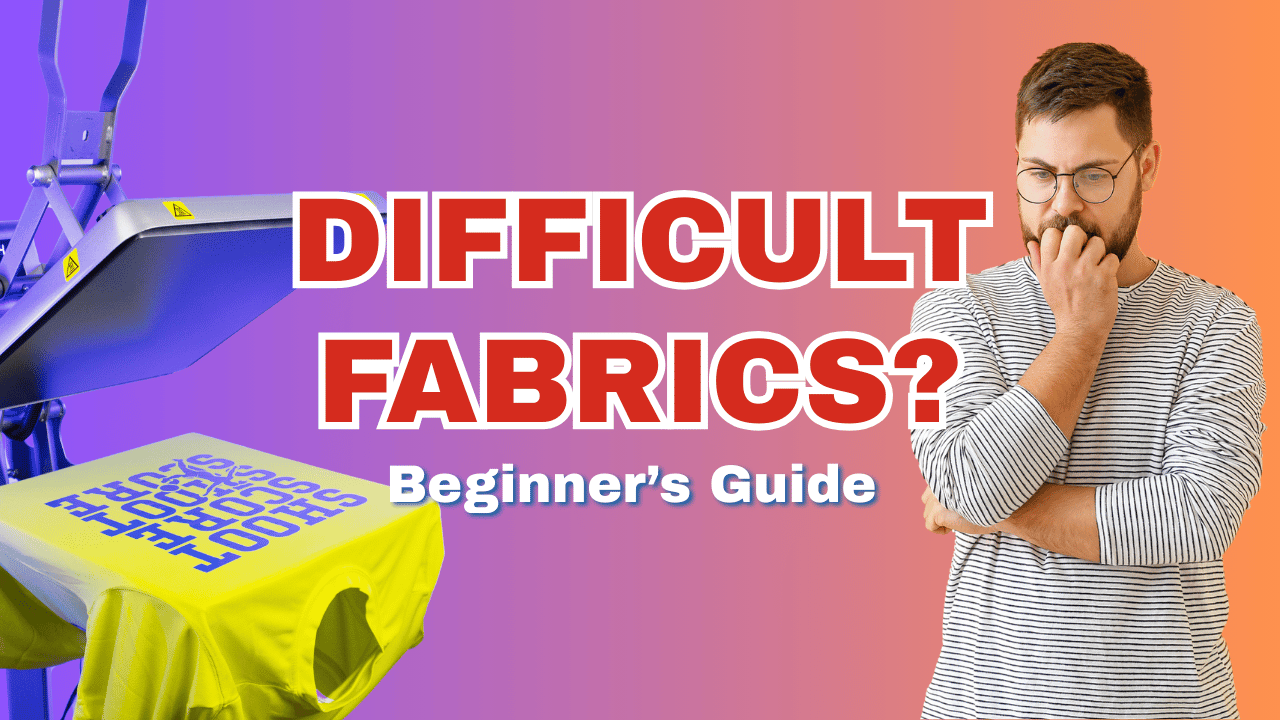

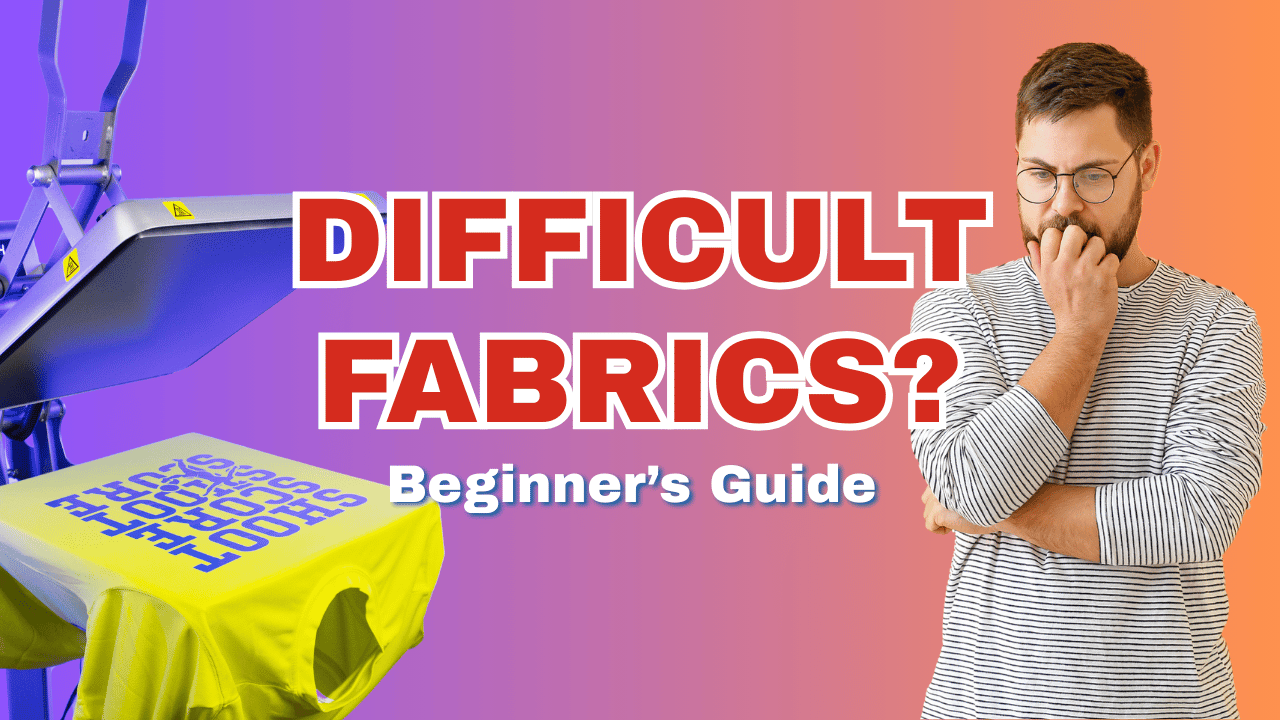

A Beginner’s Guide to Pressing Difficult Fabrics

Not all garments behave the same on a heat press. While cotton tees are straightforward, materials like polyester, nylon, softshell and performance wear require a little more care. For beginners, these “difficult fabrics” are often where misprints happen, but they don’t have to be.

With the right settings, materials, and preparation, you can confidently press almost any fabric and deliver professional results every time.

This guide breaks down what makes certain fabrics challenging and exactly how to handle them.

Why Some Fabrics Are Harder to Print

Difficult fabrics usually share one of these traits:

- They’re heat-sensitive

- They’re coated or water-resistant

- They contain high levels of synthetic fibres

- They have texture or stretch

These factors affect how well the transfers bond, how the ink behaves and how much heat the garment can tolerate.

The key is adjusting your process and not forcing the fabric to behave like cotton.

Polyester is popular for sportswear and workwear, but it’s prone to dye migration, where garment dyes rise into the transfer after pressing.

How to press it successfully:

- Use transfers designed for low-temperature applications

- Reduce dwell time where possible

- Always test for dye migration before production

- Avoid over-pressing

Beginner tip: If a white transfer turns pink or grey after a day, dye migration is the cause, not poor pressing.

Nylon jackets, bags and coated garments often have finishes that resist heat and adhesives.

How to press it successfully:

- Use nylon-specific transfer materials

- Apply firm, even pressure

- Keep temperature controlled and precise

- Pre-press to remove moisture

Beginner tip: If a transfer peels easily from nylon, the issue is usually transfer choice, not press pressure.

Softshell jackets and stretch garments need flexibility. A rigid transfer can crack over time.

How to press it successfully:

- Choose flexible ink or vinyl formulations

- Avoid overstretching the garment on the platen

- Allow full cooling before peeling

Beginner tip: Stretch fabrics often need slightly lower pressure than thick cotton hoodies.

Printing over seams, zips or pockets causes uneven pressure, leading to partial adhesion.

How to press it successfully:

- Use threadable platens to avoid raised seams

- Position prints away from zips and pockets

- Use pressing pillows to lift uneven areas

Beginner tip: Never force a platen closed over bulky seams, uneven pressure is guaranteed.

Before running any difficult-fabric job:

- Press a sample

- Wash test it

- Check for peeling, fading or dye bleed

This five-minute test prevents costly reprints later.

Once you understand how different fabrics react to heat, pressing difficult materials becomes routine rather than risky. With accurate temperature control, reliable pressure and fabric-specific transfer materials, even challenging garments deliver consistent, professional results.

Start a small swatch library of garment types and tested settings. Over time, you’ll build your own foolproof reference that speeds up quoting, setup, and production.